The requirements of GaN USB PD fast charging for aluminum electrolytic capacitors:

Application background:

As the screens of electronic products become larger and larger, the power of the charger also increases, especially for high-power fast-charging chargers, the current status of the charger cannot be changed by using traditional power devices. The GaN technology combined with the introduction of the USB PD fast charging reference design enables the current common 45W adapter design to adopt a 30W or smaller form factor design. The rapid development of 5G, all associated devices using USB, put forward new requirements and challenges for battery life. Gallium nitride meets the USB PD fast charging charger, accelerating the popularization of light, thin and miniaturized chargers, and has become a new growth opportunity in the power supply field.

At the same time, the large-capacity and miniaturization demand of the indispensable input high-voltage filter liquid aluminum electrolytic capacitors continues to rise, ushering in new opportunities and challenges

Corresponding to the requirements of aluminum electrolytic capacitors:

◆ The installation space limit restricts the innovation and upgrading of fast-charging products. Large-volume electrolytic capacitors directly affect the compact layout of fast-charging PCBs and cannot be implemented smoothly and efficiently.

◆ The electrolytic capacitor can be more miniaturized (smaller height and a thinner diameter under the same capacity)

◆ The standby power is large, the power conversion efficiency is low, and the energy efficiency level is difficult to reach the standard

◆ The electrolytic capacitor has a large leakage current, poor ripple resistance (high impedance), and large energy loss, making it difficult for fast charging to meet the international energy efficiency level VI requirements

◆ Miniaturized electrolytic capacitors have low leakage current and stronger ripple resistance (lower ripple temperature rise and lower impedance under miniaturization)

◆High power density, high heat when charging, insufficient working life, poor user experience

◆ The electrolytic capacitor has poor filtering ability and large heat generation, which accelerates the deterioration of the fast-charging components and shortens the working life.

◆ Miniature electrolytic capacitors have strong ripple resistance (small ripple temperature rise and lower impedance under miniaturization), insufficient lightning resistance, and direct failure in harsh environments, leading to user complaints and complaints

◆The electrolytic capacitor has insufficient withstand voltage and poor resistance to instantaneous surges, causing the breakdown of fast-charging components

◆ Miniaturized electrolytic capacitors have the strong anti-surge capability (guaranteed to withstand voltage under miniaturization)

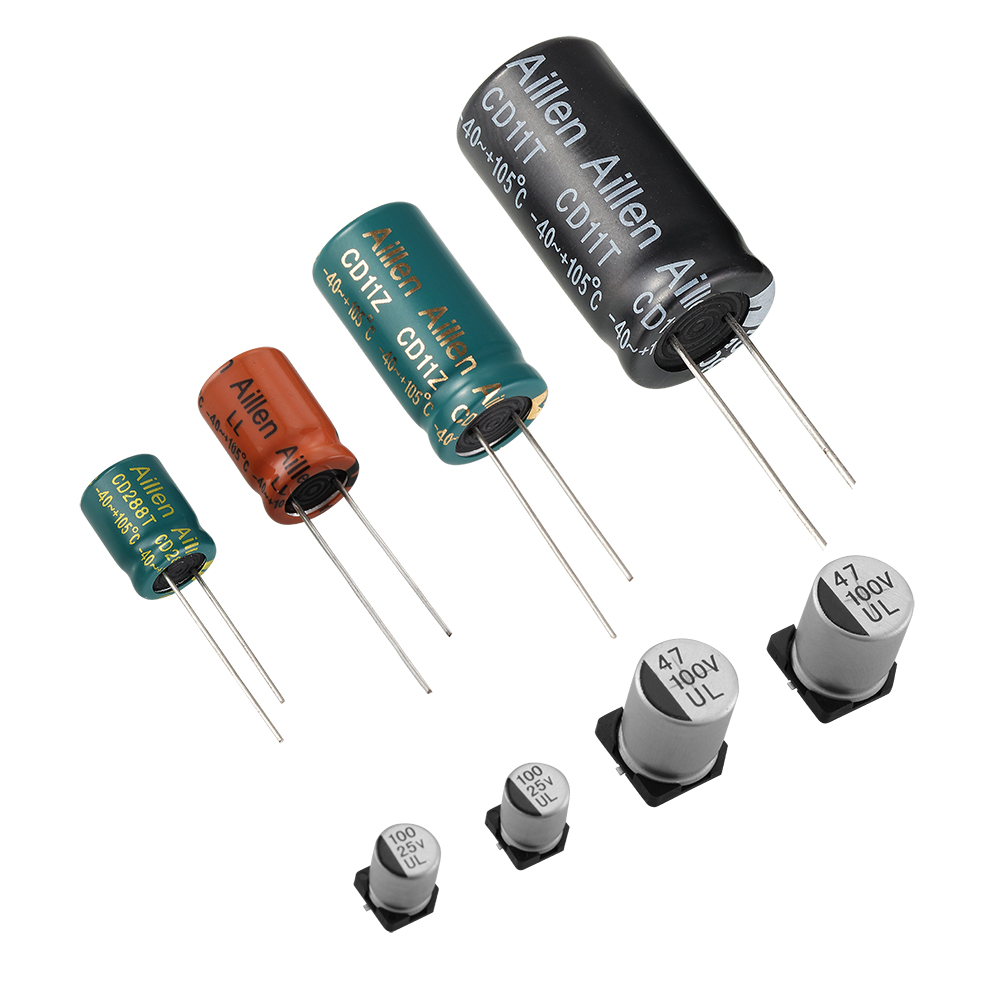

Aillen has special products to deal with—the series remains unchanged, but internal customization (requirements: large capacity, miniaturization, low leakage current, high ripple, low impedance, anti-lightning products. Purpose: increase capacity, reduce Impedance, improve ripple current resistance and lightning surge resistance, suitable for fast charging sources and adapters, etc.)

Aillen solves the above problems according to the following design plan:

◆ Enlarge the electrode foil area (under the condition of ensuring the same voltage, use high specific capacitance positive foil)

◆ Reduce the loss of electrolyte (to ensure that the flash voltage remains unchanged, use high-conductivity electrolyte)

◆ Improve the resistance to breakdown and voltage resistance of electrolytic paper (in order to ensure the constant voltage resistance value, electrolytic paper with low ERS value is used)

◆ Improve production equipment technology to enhance manufacturing accuracy (use equipment with stable performance for production, while special plane control)